WASHINGTON — The U.S. Air Force is experimenting with a mix of drones, artificial intelligence and cloud collaboration to find ways to slash the time it takes to inspect aircraft for wear and tear.

In trials backed by aircraft manufacturer Boeing and Near Earth Autonomy, a developer of drone operating systems, service technicians at Joint Base Pearl Harbor-Hickam in Hawaii are launching autonomous uncrewed aerial systems with mounted cameras to catalog the condition of Boeing C-17 cargo planes that transport heavy weapons and passengers.

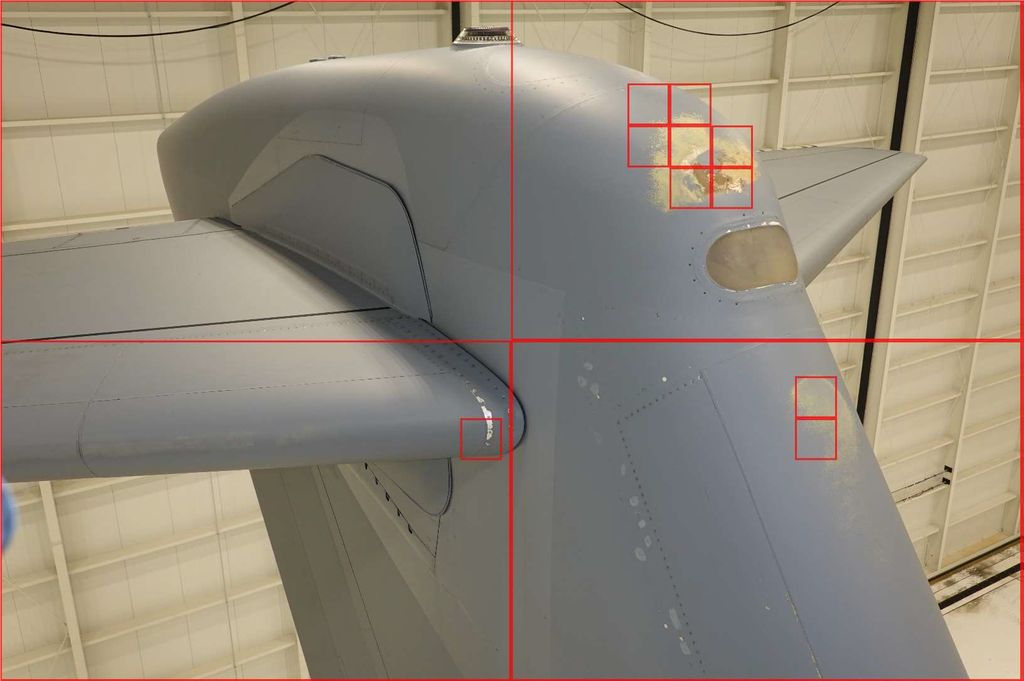

The goal is to reduce the complexity of aircraft checkups while also improving the accuracy and reliability of information. Whereas traditional exterior examinations can take hours and still miss tiny details, the drone-centric approach, fueled by pattern recognition and 3D models, is far quicker and feeds verified observations to a secure repository, officials said.

“A preflight inspection right now can take up to four hours. We can do it in 30 minutes. That is a significant time savings for airmen and making sure that the aircraft is available, ready to go,” Alli Locher, a manager with Near Earth Autonomy, told reporters June 27 at an event in Virginia. “Eventually you’ll be able to just pull up a tail number, click anywhere on that 3D model of that aircraft and be able to see a history of images of that exact part you clicked on, from anywhere in the world over the life of the aircraft.”

As the U.S. Defense Department prepares for potential fights in the Indo-Pacific region and Europe, the Air Force is pursuing a concept known as Agile Combat Employment. ACE envisions a hub-and-spoke layout of bases: some larger and fixed, some smaller and mobile.

RELATED

Such an approach will spread out human effort and know-how — resources already in high demand — so having a reliable, centralized means of collecting and evaluating the status of an aircraft will be all the more important, according to Scott Belanger, a Boeing Global Services executive. Boeing is the third-largest defense contractor in the world when ranked by defense revenue.

“The pictures are, literally, instantaneously live, sent to a cloud environment, where they can be analyzed by Near Earth Autonomy software and our automated damage detection software,” he said. “We’re not trying to replace the human inspection. We’re trying to inform it. We’re trying to upskill that human inspection so when they do go on the tail, they’re not guessing: They know exactly what to bring, they know exactly what to expect.”

In testing, the drones and associated routines have detected “up to 76%, 78% damage,” according to Belanger. While that’s a “high C,” he said, it beats out the human-only metric of 50%.

Moving forward, Boeing and Near Earth Autonomy are eyeing more payloads for the drones, to potentially catch subsurface damage, as well as adding more aircraft to the inspection roster. Lockheed Martin’s C-5 plane was most recently programmed, according to Locher. Boeing’s KC-135 and KC-46 could be next.

“Our secret sauce here, that we use, is we have an autonomy back end on this drone that always knows where it is relative to the aircraft, not the environment around it,” Locher said. “With that, you can pretty much run any sensor and get a map of that sensor.”

Colin Demarest was a reporter at C4ISRNET, where he covered military networks, cyber and IT. Colin had previously covered the Department of Energy and its National Nuclear Security Administration — namely Cold War cleanup and nuclear weapons development — for a daily newspaper in South Carolina. Colin is also an award-winning photographer.